Blog/2024.08.08

With the continuous advancement of science and technology and the iterative updating of technology, traditional LED display packaging technology has gradually been unable to meet the high standards of modern display requirements. It is against this backdrop that COB (Chip-on-Board) packaging technology emerged, bringing about a profound technological innovation in the LED display industry.

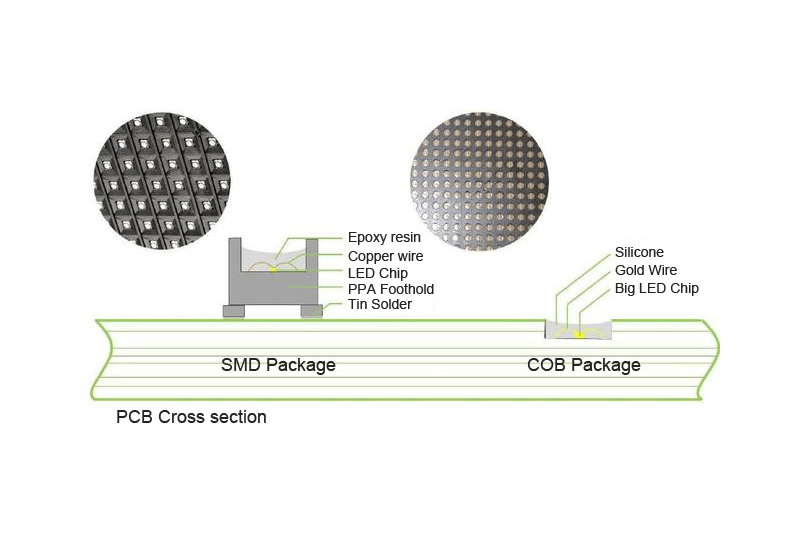

Traditional LED display packaging technologies, such as SMD (Surface Mount Technology), have met market demands to a certain extent. However, as expectations for display quality, stability, and production costs continue to rise, their limitations have become increasingly apparent. For instance, the processes of manufacturing and soldering the LEDs in SMD packaging not only add complexity to the production process but may also impact the thermal performance and stability of the display.

To overcome these technical barriers, COB (Chip-on-Board) packaging technology has emerged. It directly integrates LED chips onto the printed circuit board (PCB), eliminating the need for traditional LED-making steps and achieving direct connection between the chip and the substrate. This method not only streamlines the production process but also significantly enhances the overall performance of the display screen.

I. Definition of COB Packaging

COB (Chip on Board) is a kind of LED display packaging technology. LED light-emitting chips are directly bonded to the module board with high precision and connected to driver components on the module board through special media for overall protection of the light-emitting surface. COB packaging eliminates the two key procedures of turning LED chips into lamp beads and reflow soldering as compared to standard SMD packaging.

II. Principle of COB Packaging

Wire Bonding COB. In wire bonding COB Also called (face-up cob or Lateral COB), the LED chips are attached directly to the substrate using an adhesive, and their electrical connections are made with thin wire leads. This method is quite traditional and widely used due to its cost-effectiveness and simplicity in connecting the LED chips to the driving electronics.

III. Advantages of COB Packaging

High Resolution and Clarity

COB packaging achieves smaller pitch and higher pixel density by directly bonding LED chips to the PCB, leading to a finer and clearer image quality, ideal for high-resolution display applications.

Slim Design

COB packaging does away with the separate LED LEDs structure, resulting in a thinner and lighter display, which is not only easier to install and transport but also aesthetically pleasing and modern.

Efficient Heat Dissipation

COB technology allows LED chips to be directly bonded to the PCB, facilitating rapid heat conduction and improving thermal efficiency, which extends the lifespan of LED displays and ensures stable performance.

Enhanced Protection

The overall structure of COB packaging enhances the dust-proof, waterproof, and shock-resistant capabilities of LED displays, making them more suitable for harsh environments and improving their reliability and durability.

Wide Viewing Angle

COB packaging typically employs shallow concave spherical lighting technology, achieving a wide viewing angle of over 175 degrees, providing an immersive viewing experience, especially for wide-viewing applications.

Simplified Production Process

The COB packaging process is relatively simple, facilitating mass production and reducing costs, making it more competitive in commercial applications.

IV. LED Display Models Using COB Packaging Technology

As the technology matures and becomes more widespread, an increasing number of LED displays are adopting COB packaging technology. This is particularly true in the field of small-pitch LED displays, such as models P1.25 and P0.93, where COB has become the technology of choice. These displays have gained wide market recognition for their outstanding image quality and stability.

V. Main Application Areas of COB LED Displays

Commercial Advertising and Media

Outdoor Billboards: COB displays’ high brightness and contrast make them ideal for outdoor advertising, attracting more attention and enhancing the effectiveness of advertisements.

Indoor Advertising Machines: In high-traffic areas like malls, airports, and train stations, COB displays are used for commercial advertising, clearly presenting content and increasing ad appeal.

Traffic and Security Monitoring

Traffic Information Screens: On highways and urban thoroughfares, COB displays show traffic information and road condition alerts, ensuring the real-time and accurate transmission of information with high reliability.

Security Monitoring Centers: COB displays are used in security monitoring centers to aggregate video feeds from various monitoring points, offering high resolution and seamless splicing for clear and continuous surveillance images.

Education and Training

Multimedia Classrooms: COB displays are used to present educational content, helping students understand knowledge better with high-definition and detailed imagery.

Training Centers and Corporate Meeting Rooms: These venues use COB displays to present training materials and meeting content, enhancing the efficiency and quality of information delivery.

Sports and Entertainment

Sports Venues: In stadiums and arenas, COB displays provide real-time coverage of matches and score information, offering an immersive viewing experience for spectators.

Entertainment Venues: At concerts and live events, COB displays show performance information and background visuals

+86-(0)731-84539619

Hunan Yestech Optoelectronic Co., Ltd. Terms of Service Privacy Policy Powered by szweb